When General Motors rolled out its "skateboard" vision for a fuel cell car at the 2002 Detroit auto show in January, there was buzz, and there was a big question.

The skateboard concept, called Auto-nomy, was the product of GM's Design and Technology Fusion Group, and it radically reordered automobile physiology: Fuel cells, hydrogen, motor, and brakes were all crammed into a 15-foot-long, 6-inch-thick chassis onto which modular car bodies could be snapped. Drive-by-wire controls would plug into the skateboard's computer brain through a docking port. With all of the important mechanicals belowdecks, the car could be configured for maximum space and utility. An owner could trade in a sedan for a pickup by simply having the new body snapped onto his skateboard.

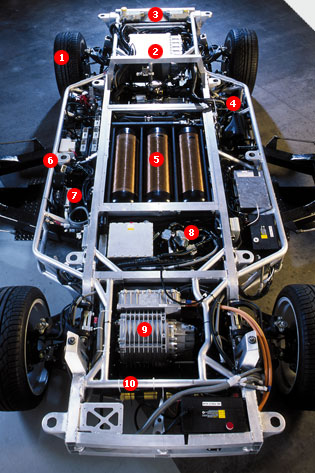

Fuel cell and by-wire technology frees engineers to flatten the chassis into an 11-inch- thick pancake of steel and wires. from the rear of the platform, the by-wire brakes

(1) are activated by a computer-controlled signal, not hydraulic pressure. the fuel cell stack

(2) creates electricity from hydrogen, which releases its excess heat and water vapor via metal fins on the radiator

(3) Hydrogen, ostensibly from a refueling station in a town near you, enters through a valve on the side of the vehicle

(4) and replenishes three compressed hydrogen tanks

(5) A high priority of hydrogen storage research is ensuring these don't leak during a crash. Two types of supports connect the skateboard to the passenger cabin: body mounts

(6) provide a strong physical connection, and the universal docking port

(7) links cockpit controls to computerized systems on the platform. The by-wire inputs snake through this port on their way to the main by-wire system controls

(8) which send commands to the brakes, electric engine

(9) and by-wire steering rack

(10) Future Hy-wire prototypes may incorporate four smaller engines, one per wheel, as in the autonomy concept.

Bold, no doubt. But the question was: Is this doable? Even GM conceded that the technology did not exist to get the fuel cell and hydrogen tank into a 6-inch skateboard, and might not for years. Nor were the powerful, hub-mounted electric motors—one for each wheel in the Autonomy configuration—available.

GM did promise, however, to show a proof-of-concept vehicle before the end of this year, and at the recent Paris Motor Show the company rolled out a driveable prototype called Hy-wire (HYdrogen meets by-WIRE, get it?). The images on these pages provide a fascinating look at how an ambitious vision is tweaked and compromised as a company moves from concept to working prototype with provisional technology in hand and an eye on production in distant 2010.

With hub-mounted motors unavailable, Hy-wire employs a single electric motor to power the front wheels. GM adopted the same 94-kilowatt (129-kW peak) fuel cell powerplant and drivetrain used in its 2001 Opel-based HydroGen3 fuel cell vehicle; instead of a 6-inch- thick chassis, this required an 11-inch skateboard that fattens to 17 inches at the rear to provide clearance for the fuel cell stack. The promised 300-mile range is currently limited to 80 miles by the capacity of Hy-wire's compressed hydrogen tanks, which top out at 5,000 psi.

The company chose a luxury sedan as the body style for Hy-wire because a utilitarian minivan shape would imply that the fuel cell system still required the volume of a large vehicle. "If you can do a car, it is obvious that you can do a taller vehicle," says Chris Borroni-Bird, who joined the Fusion group as director in 2000, cooked up the Autonomy concept last year, and then partnered with two European companies this spring to fast-track Hy-wire for the Paris show.

At the Geneva show in March, Borroni-Bird had seen the Filo drive-by-wire concept car produced by Italian design house Stile Bertone. Filo was a joint effort with the Swedish SKF Group, which builds by-wire systems for aircraft and wanted to break into the growing market for by-wire auto technology. In Filo, a single airplane-style control yoke replaced the usual steering wheel and pedals. Why not move this ready-made system into the Autonomy? By April, Borroni-Bird had struck a deal with Bertone/SKF to marry his skateboard to their by-wire technology. GM would direct the project and design the car, SKF would provide drive-by-wire control systems like the ones used in the Filo, and Bertone would assemble the final product.

Managing the transcontinental project for a September deadline was tricky, says Mohsen Shabana, the chief engineer on the Autonomy program, because there was little time to test individual systems before merging them. So the team built two rolling frames for the Hy-wire, one with battery power and one with a fuel cell, meaning the drive-by-wire systems could be tested on the frame while the more complex fuel cell problems were sorted out.

Early test drives show that concentrating weight below has yielded a very stable car. The by-wire yoke system, though, "takes a little bit of training," says Shabana. "And it would be a bit of a departure from what our customers are used to. This is an extreme way of demonstrating the capabilities of the system, not necessarily the way we will represent it in our vehicles." Translation: Expect a more conventional array in the next edition.

"We definitely feel there is a role for steering wheel and foot pedals in the near term," says Borroni-Bird. "So we are open to both approaches at this point."

The idea of snap-on bodies that drivers could change to suit their whims has been discarded, but the advantage of a modular design has not been lost. The Hy-wire body is fixed to the chassis with 10 old-fashioned rubber bushings and bolts, and GM could develop various body styles for the self-contained skateboard. "That makes so much more sense," observes Shekar Gopalan, vice president of research and consulting for Frost & Sullivan. "Now we are talking about a standard in manufacturing processes and building economies of scale."

Hy-wire's pointy nose gives occupants an unobstructed view of the road, dramatically emphasizing the space gains that come with the skateboard design. But Borroni-Bird admits this was done more for effect; safety requirements will put firewalls, airbags, and knee bolsters in future designs. "For the Hy-wire, we were just basically conveying the concept that there is no engine compartment," says Borroni-Bird.

Hy-wire is version 2.0 of a rolling initiative; GM won't say when version 3.0 will appear, but says it's working on an accelerated schedule. The next iteration will use a purpose-built fuel cell that comes closer to the 6-inch thickness standard. Hydrogen tanks will pack the fuel in at 10,000 psi to extend range.

Meanwhile, fuel cell and drive-by-wire technologies will continue to evolve in conventionally designed cars later this decade. Real-world experience with these technologies will set the stage, Borroni-Bird believes, for a realization of an Autonomy-inspired car that will deliver the advantages of the skateboard concept.

"We expect those technologies to be where they need to be in 2007 or so," he says. "Which would allow us to go into production in 2010."

—Reported by Dan Carney

Source: http://www.popsci.com/